1 / 4

64/110 (123) XLPE geïsoleerde kabel met KEMA-testrapport

| Model No. : | YJLW03 |

|---|---|

| Brand Name : | HUAYUAN YONGTONG |

| Application : | Underground |

Beijing, Beijing, China

- Distributeurgroothandel

- Fabrikant

- OEM -service

- Platformcertificering

- Video

Product beschrijving

1. ALGEMEEN

Deze vermelde specificatie heeft betrekking op de structuur, prestaties, test- en verpakkingsinformatie van EHV Power Cable zoals vervaardigd door Beijing Huayuan Gaoke Cable Co., Ltd.

Zaken die niet in deze technische specificatie worden vermeld, worden onderhandeld door koper & leverancier. Dit document bevestigt de overeenkomst tussen beide partijen als technische overeenkomst van overeenkomst, tenzij anders vermeld in officiële schriftelijke bijlagen.

2. APPLICALBE NORMEN

De kabel moet als volgt worden ontworpen, gefabriceerd en getest volgens internationale normen:

|

Quality Control Standard |

|

|

ISO 9001 |

Quality Management Systems |

|

ISO 14001 |

Environmental Management Systems |

|

Component Material Standard |

|

|

IEC 60228 |

Conductors of insulated cables |

|

Cable Standard |

|

|

IEC 60840 |

Power cables with extruded insulation and their accessories for rated voltages above 30 kV (Um = 36 kV) up to 150 kV (Um = 170 kV) – Test methods and requirements |

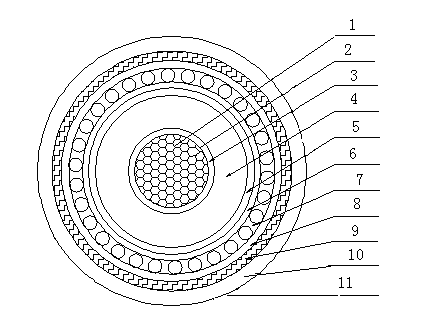

3.CABLES STRUCTUUR VOOR 110kV KABEL

(1)

CU / XLPE / AWS / AL-PE / HDPE 64/110 (123) kV 1 × 400 mm2

|

Structure |

Nominal thickness mm |

Nominal diameter mm |

|

1 Circular compact stranded copper conductor |

60/2.97 |

23.2±0.2 |

|

2 semi-conductive tape |

0.14 |

23.8 |

|

3 Conductor screen(wrapping & extruding) |

1.2 |

25.6 |

|

4 XLPE insulation |

17.5 |

60.6(-1.0,+1.5) |

|

5 Insulation screen |

1.0 |

62.6 |

|

6 semi-conductive water blocking tape |

2.0 |

64.6 |

|

7 Aluminum wire screen with aluminum tape wrapping(gap) |

Sectional area 289mm2 |

69.9 |

|

8 semi-conductive water blocking tape |

0.6 |

70.9 |

|

9 AL-PE tape |

0.21 |

71.6 |

|

10 HDPE outer sheath |

4.0 |

79.6 |

|

11 semi-conductive layer (graphite coating) |

|

79.6±3.0 |

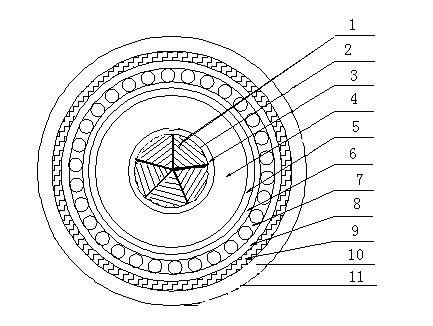

(2)

CU / XLPE / AWS / AL-PE / HDPE 64/110 (123) kV 1 × 2000 mm2

|

Structure |

Nominal thickness mm |

Nominal diameter mm |

|

1 Five(5) Milliken (segmental) copper conductor |

5*(91/2.48) |

54.7±1.0 |

|

2 semi-conductive tape |

0.14 |

55.3 |

|

3 Conductor screen(wrapping & extruding) |

2.0 |

58.7 |

|

4 XLPE insulation |

16.0 |

90.7(-1.5,+1.0) |

|

5 Insulation screen |

1.0 |

92.7 |

|

6 semi-conductive water blocking tape |

2.0 |

94.7 |

|

7 Aluminum wire screen with aluminum tape wrapping(gap) |

Sectional area 275mm2 |

100.0 |

|

8 semi-conductive water blocking tape |

0.6 |

101.0 |

|

9 AL-PE tape |

0.21 |

101.7 |

|

10 HDPE outer sheath |

5.0 |

111.7 |

|

11 semi-conductive layer (graphite coating) |

|

111.7±3.0 |

1. GEGARANDEERDE TECHNISCHE GEGEVENS

64/110 (123) kV 1 × 400mm2

|

No |

DESCRIPTION |

UNIT |

VALUEREQUIRED |

|

1 |

Manufacturer |

|

Beijing Huayuan |

|

2 |

Cable size |

mm2 |

400(nominal) |

|

3 |

Cable type |

|

CU/XLPE/AWS/AL-PE/HDPE |

|

4 |

Voltage Grade(U0/U(Um) |

KV |

64/110(123) |

|

5 |

Reference Standard |

|

IEC 60840 |

|

6 |

No. and cross sectional area of conductor |

|

1C 400sqmm |

|

7 |

Conductor material |

|

Copper |

|

8 |

Shape |

|

Circular compact stranded |

|

9 |

Nominal diameter of conductor |

mm |

23.2 |

|

10 |

Conductor Screen materials |

|

Simi-conduction tape + Extruded semi-conducting compound |

|

11 |

Nominal thickness of conductor screen |

mm |

1.2(wrapping + extruding) |

|

12 |

Insulation material |

|

super clean XLPE |

|

13 |

Nominal thickness of insulation |

mm |

17.5 |

|

14 |

Nominal diameter over insulation |

mm |

60.6 |

|

15 |

Insulation screen material |

|

|

|

16 |

Nominal thickness of insulation screen |

mm |

1.0 |

|

17 |

Metallic Screen material |

|

aluminum wire screen with aluminum spiral binder tape (gap) |

|

18 |

Short circuit current rating(t=1.0sec) |

|

|

|

|

Of conductor |

kA |

57.8 |

|

|

Of metallic screen |

kA |

28.5 |

|

19 |

Outer sheath material |

|

HDPE |

|

20 |

Nominal thickness of outer sheath |

mm |

4.0 |

|

21 |

Nominal overall diameter of cable |

mm |

79.6 |

|

22 |

Approx. weight of cable |

kg/km |

7960 |

|

23 |

Minimum bending radius |

mm |

1600 |

|

24 |

Max.D.C. Conductor resistance at20`C |

Ω/km |

0.0470 |

|

25 |

Nominal capacitance per phase |

uF/km |

0.155 |

|

26 |

Max. current rating in air at 40° C |

A |

752(1 circuit ,phase spacing 250, flat formation, a point earthed or cross connected) |

|

27 |

Max. current rating in ground at 25° C |

A |

721(1 circuit ,phase spacing 250, flat formation, a point earthed or cross connected ,depth of laying 1200 mm ,thermal resistivity of soil 1.2 k.m/W,25℃) |

|

28 |

Max. conductor temperature on continuous |

℃ |

90 |

|

29 |

Max. conductor temperature in short circuit |

℃ |

250(not exceed 5s) |

64/110 (123) kV 1 × 2000mm2

|

No |

DESCRIPTION |

UNIT |

VALUEREQUIRED |

|

1 |

Manufacturer |

|

Beijing Huayuan |

|

2 |

Cable size |

mm2 |

2000(nominal) |

|

3 |

Cable type |

|

CU/XLPE/AWS/AL-PE/HDPE |

|

4 |

Voltage Grade(U0/U(Um) |

KV |

64/110(123) |

|

5 |

Reference Standard |

|

IEC 60840 |

|

6 |

No. and cross sectional area of conductor |

|

1C 2000sqmm |

|

7 |

Conductor material |

|

Copper |

|

8 |

Shape |

|

Five(5) Milliken (segmental) |

|

9 |

Nominal diameter of conductor |

mm |

54.7 |

|

10 |

Conductor Screen materials |

|

Simi-conduction tape + Extruded semi-conducting compound |

|

11 |

Nominal thickness of conductor screen |

mm |

2.0(wrapping + extruding) |

|

12 |

Insulation material |

|

super clean XLPE |

|

13 |

Nominal thickness of insulation |

mm |

16.0 |

|

14 |

Nominal diameter over insulation |

mm |

90.7 |

|

15 |

Insulation screen material |

|

Extruded semi-conducting compound |

|

16 |

Nominal thickness of insulation screen |

mm |

1.0 |

|

17 |

Metallic Screen material |

|

aluminum wire screen with aluminum spiral binder tape (gap) |

|

18 |

Short circuit current rating(t=1.0sec) |

|

|

|

|

Of conductor |

kA |

287.4 |

|

|

Of metallic screen |

kA |

26.2 |

|

19 |

Outer sheath material |

|

HDPE |

|

20 |

Nominal thickness of outer sheath |

mm |

5.0 |

|

21 |

Nominal overall diameter of cable |

mm |

111.7 |

|

22 |

Approx. weight of cable |

kg/km |

24590 |

|

23 |

Minimum bending radius |

mm |

2240 |

|

24 |

Max.D.C. Conductor resistance at20`C |

Ω/km |

0.009 |

|

25 |

Nominal capacitance per phase |

uF/km |

0.306 |

|

26 |

Max. current rating in air at 40° C |

A |

1984(1 circuit ,phase spacing 250, flat formation, a point earthed or cross connected) |

|

27 |

Max. current rating in ground at 25° C |

A |

1597(1 circuit ,phase spacing 250, flat formation, a point earthed or cross connected ,depth of laying 1200 mm ,thermal resistivity of soil 1.2 k.m/W,25℃) |

|

28 |

Max. conductor temperature on continuous |

℃ |

90 |

|

29 |

Max. conductor temperature in short circuit |

℃ |

250(not exceed 5s) |

5. TESTVEREISTEN VOOR EHV-STROOMKABELS

De kabeltests moeten worden uitgevoerd in overeenstemming met de toepasselijke norm van 110 kV voedingskabels. De volgende testitems moeten worden uitgevoerd in overeenstemming met de relevante IEC-normen.

|

No. |

Test item |

|

Routine tests |

|

|

1 |

Partial discharge test |

|

2 |

Voltage test |

|

3 |

electrical test on over sheath of the cable |

|

Sample tests |

|

|

1 |

conductor examination |

|

2 |

measurement of electrical resistance of conductor and of metal screen/sheath |

|

3 |

measurement of thickness of insulation and oversheath |

|

4 |

measurement of thickness of metal sheath |

|

5 |

measurement of diameters |

|

6 |

hot set test for XLPE insulation |

|

7 |

measurement of capacitance |

6. VERPAKKINGSGEGEVENS VOOR 64/110 KV STROOMKABELS

De kabels moeten op stalen vaten worden gewonden. De onuitwisbare markering moet worden afgedrukt op het oppervlak van de trommelflens in overeenstemming met de eisen van de klant.

|

Cable Type |

Drum length(m) |

Drum Dimensions (mm) |

|||

|

|

|

D |

d |

b |

B |

|

CU/XLPE/AWS/HDPE 64/110kV 1× 400 mm2 |

900 |

3200 |

2000 |

1950 |

2200 |

|

CU/XLPE/AWS/HDPE 64/110kV 1× 2000 mm2 |

400 |

3600 |

2600 |

1950 |

2200 |

Fabriek en uitrusting

Pakket en levering

Eer

Beijing, Beijing, China

- Distributeurgroothandel

- Fabrikant

- OEM -service

- Platformcertificering

- Video

Stuur uw aanvraag naar deze leverancier